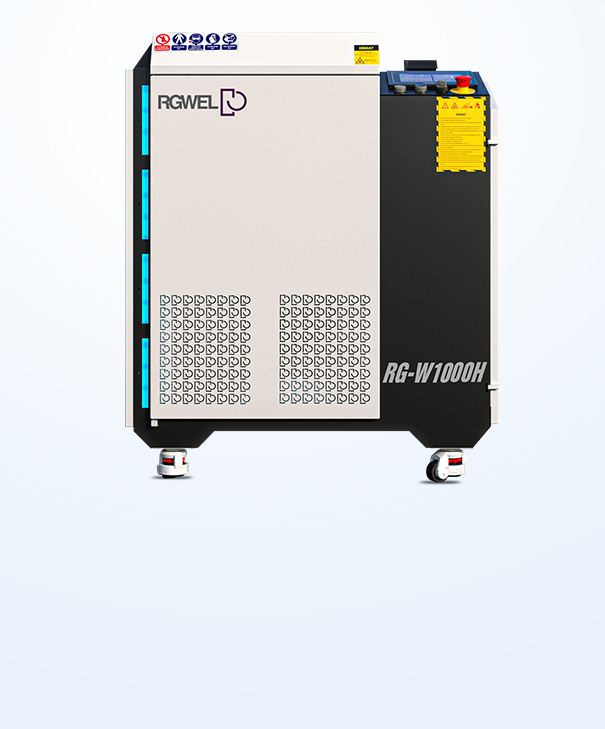

Handheld Fiber Laser Welding Machine

Handheld fiber laser welding machines are compact, mobile and operator-friendly systems developed for flexible sheet metal and stainless fabrication.

Thanks to the fiber laser source, stable optical output and ergonomic welding gun, they provide fast, aesthetic and low-heat welding on many industrial materials.

They are the ideal choice for workshops, stainless furniture manufacturers, maintenance teams and companies that need to weld in different locations within the plant.

What Is a Handheld Fiber Laser Welding Machine?

A handheld fiber laser welding machine is a portable welding system that allows the operator to perform laser welding manually using an ergonomic laser gun.

Compared to TIG/MIG methods, it produces a cleaner, narrower and stronger weld seam with much less heat input.

Because the laser energy is transmitted through fiber optics, the power unit can stay stationary while the operator freely moves the welding gun.

This structure is especially preferred for sheet metal fabrication, stainless equipment, on-site repairs and parts that cannot be brought to a fixed welding station.

Technical Specifications of Handheld Fiber Laser Welding Machines

| Specification | Value |

|---|---|

| Laser Power | 1000 W – 2000 W (model dependent) |

| Laser Wavelength | 1080 nm fiber laser |

| Applicable Materials | Stainless steel, carbon steel, galvanized sheet, aluminum, copper, brass |

| Operating Mode | Continuous / pulse-supported laser welding |

| Welding Speed | 2–4× faster than TIG/MIG (application dependent) |

| Cooling System | Industrial water chiller / integrated water cooling |

| Power Supply | 220V / 380V AC (depending on model) |

| Control Interface | Touch control + preset welding parameters |

| Wire Feeding | Optional automatic wire feeding module |

Advantages of Handheld Fiber Laser Welding Machines

Production Efficiency

High-energy laser beam and fast travel speed reduce cycle times and increase daily output.

Less Post-Processing

Because the weld seam is clean and spatter-free, grinding and polishing requirements are minimized.

Material Versatility

Supports different metals such as stainless steel, carbon steel, aluminum and galvanized sheet with proper parameters.

Energy Efficiency

Fiber laser technology consumes less energy than conventional welding methods, lowering operating costs.

Application Areas of Handheld Fiber Laser Welding Machines

-

Stainless steel furniture and decorative metal products

-

Kitchen, hotel and industrial catering equipment

-

Advertising and signage fabrication

-

Automotive maintenance, bodywork and spare parts

-

Sheet metal workshops and contract manufacturing

-

On-site repair and assembly jobs

-

Railings, doors, frames and architectural metal works