Lazer Kaynağının, Geleneksel Kaynak Yöntemlerinden Farkı Nedir?

| Diğer Kaynak Yöntemleri | Lazer Kaynak | |

| Malzemeye İşlenen Sıcaklık | Çok Yüksek | Düşük |

| Malzemedeki Deformasyon %'si | 90% | 5% |

| Malzemedeki Kaynak Mukavemeti | Düşük | Yüksek |

| Kaynak Sonrası Tesfiye İşçilikleri | Taşlama, Parlatma, Polisaj | Yok veya %10 Taşlama |

| Kaynak Hızı | 10% | %90 (8kat'a kadar daha hızlı) |

| Kullanım Zorluğu | Karmaşık ve Ustalık İsteyen | Basit ve Ustalık Gerektirmeyen |

| Sarf Malzeme Gideri | Yüksek | Az |

| Operatör Güvenliği | Yok | Üst Düzey |

| Kaynak Genişliği | Sabit | Ayarlanabilir 0.8mm - 5mm |

| Tel Besleme | Var | Beslemeli veya Beslemesiz Kullanabilme |

| Kaynak Nufuziyeti | Sabit | Ayarlanabilir 0mm - 8mm |

| Enerji Tüketimi | Yüksek | Düşük |

| Çevreye Etkisi | Çevre Kirliliğine Yol Açar | Çevre Dostu |

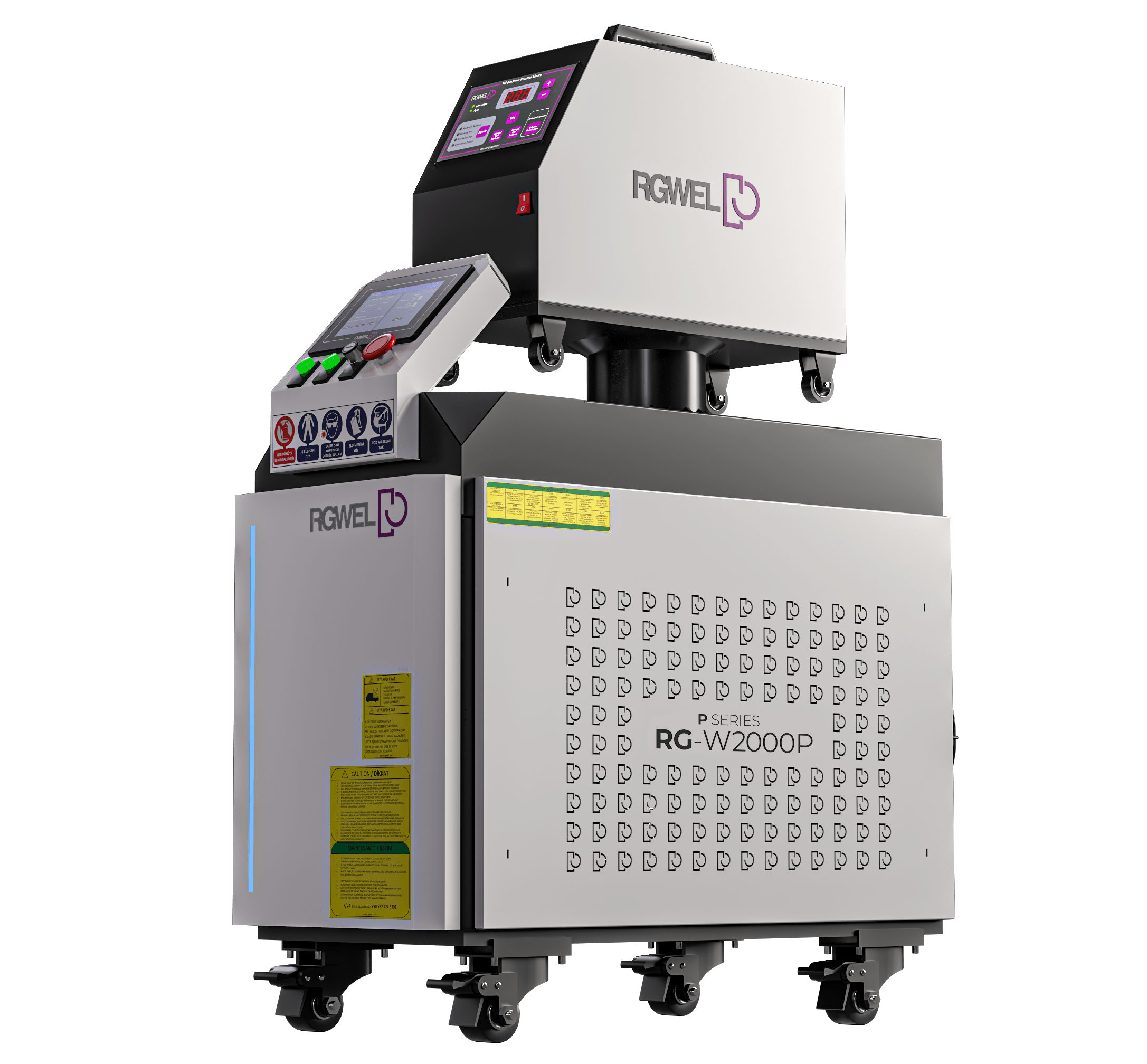

Teknik Parametreler

| Teknik Parametreler | |

| Makine Tipi | El Tipi |

| Lazer Gücü | 1500W/1,5kW |

| Lazer Kaynak Tipi | Fiber |

| Nokta Boyutu | 0.2mm - 5mm |

| Kaynak Nufüziyeti | 0.8mm - 6mm |

| Lazer Dalga Boyu | 1080nm |

| Darbe Genişliği | ≤10ms |

| Toplam Kullanılan Enerji | 8 kW |

| Soğutma Tipi | Su Soğutma (Chiller) |

Kaynak Parametreleri

| Kaynak Parametreleri | |||

| Lazer Gücü/Kalınlık | Siyah Malzeme | Çelik | Alimunyum |

| 1000w | 4mm | 3mm | 2mm |

| 1500w | 6mm | 4mm | 3,5mm |

| 2000w | 8mm | 5mm | 4,5mm |

Special Price, Service and Financing Advantages for Türkiye

RG-W1500P is designed for industrial use and is suitable for high-speed and uninterrupted operation with its 1500W laser power. It is widely preferred in both indoor and outdoor applications.

-

Local spare part and service support

-

Fast delivery

-

Free setup and operator training

-

Low maintenance and long service life

-

High welding quality and efficiency

Value Added by the Product

-

1500W laser power provides efficient and stable welding even on thick materials

-

High-speed welding with deep penetration

-

Low heat effect and minimum deformation on welding seams

-

Strong and durable welding results

-

Stable welding quality even during long-term use

Application Areas and Case Studies

-

Automotive – chassis parts, metal components, special production lines

-

Industrial manufacturing – stainless steel, aluminum and carbon steel parts

-

Machinery – general manufacturing, repair and field applications

-

White goods – inner parts, metal frames, outer surfaces

-

Aerospace – lightweight and durable metal components

Comparative Overview – 1000W / 1500W / 2000W

-

1000W: Ideal for thin and medium materials, high-speed welding

-

1500W: Deep penetration, minimal deformation, suitable for industrial production

-

2000W: Maximum power, deeper penetration, suitable for very thick materials

Purchase Guide – Handheld Fiber Laser Welding Machine

-

If the production volume is medium – high, 1500W is recommended

-

Field applications, maintenance and repair operations

-

For thin and thick materials where a stable welding seam is required

-

If long-term, durable and high-quality welding is needed

Professional technical team and free support are provided for selecting the right model.

How can we help?

For questions or quote requests, you can reach us via the contact form or call our number for the fastest support.

Turkey’s Leading Laser Technology and Machine Manufacturer – Rgwel

Rgwel offers high-precision, energy-efficient, and long-lasting solutions in laser welding, laser cutting, laser marking, laser cleaning, and robotic laser systems.

Discover the most suitable laser machine for your needs from the categories below.