Lazer Kaynağının, Geleneksel Kaynak Yöntemlerinden Farkı Nedir?

| Diğer Kaynak Yöntemleri | Lazer Kaynak | |

| Malzemeye İşlenen Sıcaklık | Çok Yüksek | Düşük |

| Malzemedeki Deformasyon %'si | 90% | 5% |

| Malzemedeki Kaynak Mukavemeti | Düşük | Yüksek |

| Kaynak Sonrası Tesfiye İşçilikleri | Taşlama, Parlatma, Polisaj | Yok veya %10 Taşlama |

| Kaynak Hızı | 10% | %90 (8kat'a kadar daha hızlı) |

| Kullanım Zorluğu | Karmaşık ve Ustalık İsteyen | Basit ve Ustalık Gerektirmeyen |

| Sarf Malzeme Gideri | Yüksek | Az |

| Operatör Güvenliği | Yok | Üst Düzey |

| Kaynak Genişliği | Sabit | Ayarlanabilir 0.8mm - 5mm |

| Tel Besleme | Var | Beslemeli veya Beslemesiz Kullanabilme |

| Kaynak Nufuziyeti | Sabit | Ayarlanabilir 0mm - 8mm |

| Enerji Tüketimi | Yüksek | Düşük |

| Çevreye Etkisi | Çevre Kirliliğine Yol Açar | Çevre Dostu |

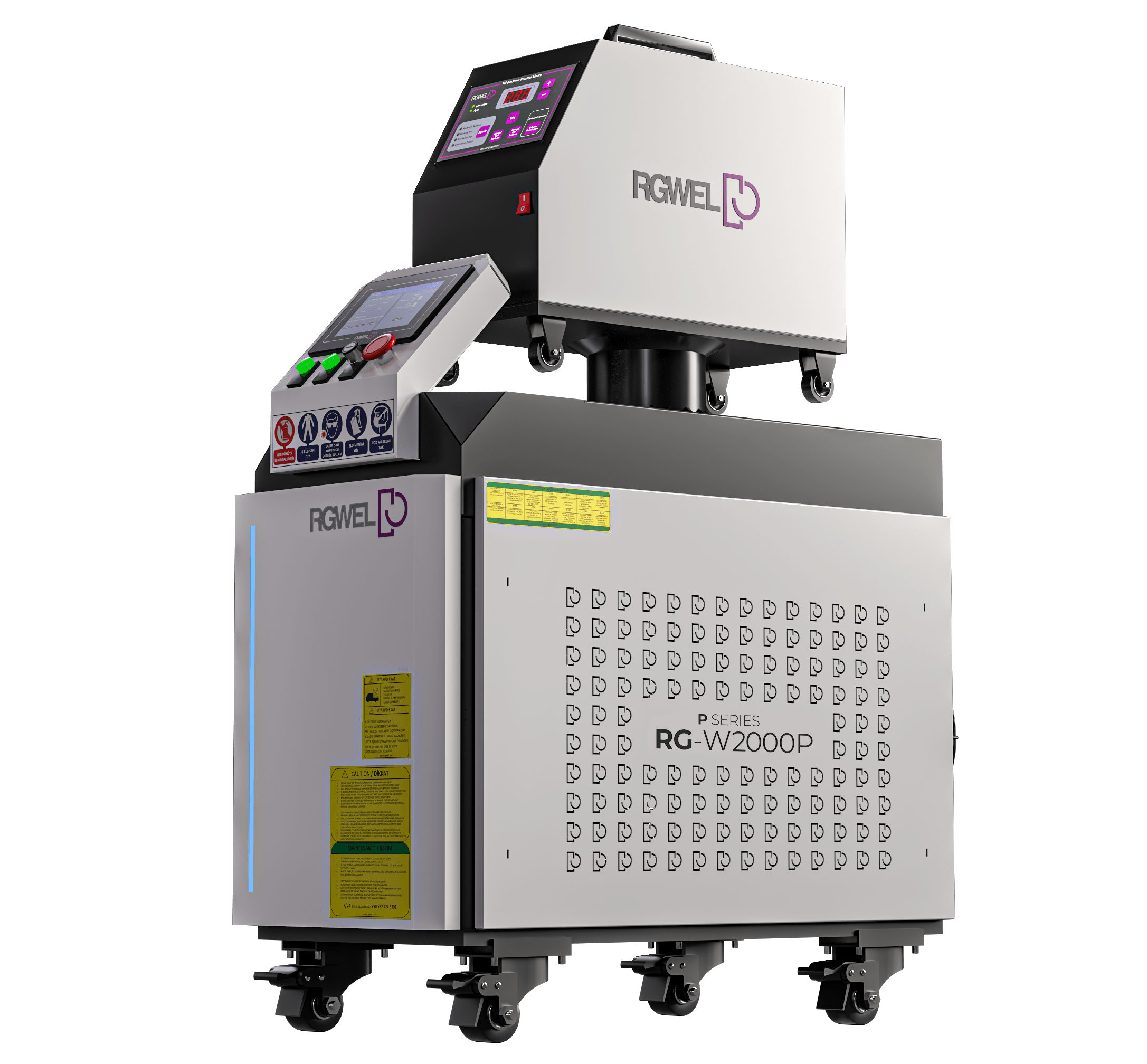

Teknik Parametreler

| Teknik Parametreler | |

| Makine Tipi | El Tipi |

| Lazer Gücü | 2000W/2kW |

| Lazer Kaynak Tipi | Fiber |

| Nokta Boyutu | 0.2mm - 5mm |

| Kaynak Nufüziyeti | 0.8mm - 8mm |

| Lazer Dalga Boyu | 1080nm |

| Darbe Genişliği | ≤10ms |

| Toplam Kullanılan Enerji | 12 kW |

| Soğutma Tipi | Su Soğutma (Chiller) |

Kaynak Parametreleri

| Kaynak Parametreleri | |||

| Lazer Gücü/Kalınlık | Siyah Malzeme | Çelik | Alimunyum |

| 1000w | 4mm | 3mm | 2mm |

| 1500w | 6mm | 4mm | 3,5mm |

| 2000w | 8mm | 5mm | 4,5mm |

Value Added by the Product

• With 2000 W power, deeper penetration and stronger welding seam durability

• Enables high-speed welding in aluminum, stainless steel, and structural steel

• Provides high performance even in long-term continuous operation

• Wide area cleaning and oxide removal capability with the 3-in-1 function

• Minimizes deformation with low heat input

• Ensures superior finish quality especially in visible surface applications

Most Prominent Technical Features

• 2000 W Raycus / Max / IPG Fiber Laser Module option

• Maximum penetration: 0–12 mm (application dependent)

• Welding speed up to 6× compared to TIG / MIG

• Low heat input – minimal discoloration

• Dual Cooling System – Industrial chiller + internal cooling

• Stable continuous output

• Lightweight ergonomic welding gun

• 3-in-1: Welding + Cutting + Cleaning

• Optional automatic wire feeder

Turkey-Specific Price, Service and Financing Advantages

Rgwel provides fast price quotations, service support, and financing solutions for Turkey.

With our strong technical team and extensive stock, RG-W series handheld laser welding machines are always ready for fast delivery.

Advantages offered in Turkey:

• 12-month Turkey warranty

• Fast spare part supply and technical service

• Free operator training and installation

• Financing support and installment options

Industry Usage Areas & Case Studies

• Stainless steel kitchen equipment production

• Aluminum / steel door and window frame welding

• Industrial ventilation – HVAC duct applications

• Automotive sub-industry exhaust, bracket, and chassis welding

• General metal fabrication and maintenance operations

Comparison Analysis – Rgwel vs Global Competitors

| Feature | Rgwel RG-W2000P | Overseas Brands |

|---|---|---|

| Power | 2000 W Fiber Laser | 1500–2000 W typical |

| Penetration | Up to 12 mm | 6–10 mm average |

| Wire Feeding | Automatic wire feeder supported | Usually optional |

| Functionality | 3-in-1 Welding / Cutting / Cleaning | Mostly welding only |

Buying Guide – Handheld Fiber Laser Welding Machine

• If you want both productivity and deep penetration, 2000 W is the ideal choice.

• Material type, thickness, and production speed should be considered during selection.

• For gap-tolerant workpieces, automatic wire feeding provides better results.

• You may request a demo to determine the most suitable machine.

• Free operator training and installation are provided after purchase.

How can we help?

For questions or quote requests, you can reach us via the contact form or call our number for the fastest support.

Turkey’s Leading Laser Technology and Machine Manufacturer – Rgwel

Rgwel offers high-precision, energy-efficient, and long-lasting solutions in laser welding, laser cutting, laser marking, laser cleaning, and robotic laser systems.

Discover the most suitable laser machine for your needs from the categories below.